|

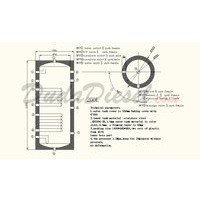

Solar Water Heaters > 200 Liter Solar Water Heater Storage Tank [tank202]

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Item Pictures |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Capacity |

Weight (Single Coil) |

Weight (Dual Coils) |

*Height |

Diameter |

Insulation Thickness |

R-Value |

Inner Tank Thickness |

Water Ports Size |

Coil Diameter |

Coil Length

|

||

Single Coil |

Dual Coil (Lower) |

Dual Coil (Upper) |

||||||||||

|

100 Liters (26.4 Gallons) |

31 kg (68 lb) |

N/A |

1100mm (43.5") |

470mm (18.5") |

50mm (1.97") |

12.45 (US) 2.19 (SI) |

1.2mm (0.047") |

3/4" NPT |

12mm (1/2") |

20m (66 ft) |

N/A

|

|

150 Liters (39.6 Gallons) |

40 Kg (88 lb) |

48 kg (106 lb) |

1500mm (59") |

20m (66 ft)

|

10m (33 ft) |

|||||||

200 Liters (53 Gallons) |

45 kg (99 lb) |

50 kg (110 lb) |

1390mm (55") |

550mm (21.6") |

1.5mm (0.06") |

15m (49 ft)

|

||||||

300 Liters (79 Gallons) |

58 kg (128 lb) |

65 kg (143 lb) |

1750mm (69") |

560mm (22") |

25m (82 ft) |

|||||||

400 Liters (105 Gallons) |

80 kg (176 lb) |

87 kg (191 lb) |

1600mm (63") |

700mm (27.6") |

60mm (2.36") |

14.95 (US) 2.63 (SI) |

2.0mm (0.08") |

1" NPT |

30m (99 ft) |

30m (99 ft) |

||

500 Liters (132 Gallons) |

90 kg (198 lb) |

97 kg (214 lb) |

1950mm (77") |

35m (115 ft) |

||||||||

600 Liters (159 Gallons) |

125 kg (275 lb) |

130 Kg (286 lb) |

1980mm (78") |

750mm (29.5") |

57.5mm (2.26") |

14.32 (US) 2.52 (SI) |

||||||

700 Liters (185 Gallons) |

145 kg (319 lb) |

150 Kg (330 lb) |

2240mm 88.2" |

40m (131 ft) |

20m (66 ft) |

|||||||

800 Liters (198 Gallons) |

206 kg (453 lb) |

210 Kg (462 Lb) |

1910mm (75") |

1000mm (39.4") |

100mm (3.94") |

24.90 (US) 4.39 (SI) |

2.5mm (0.10") |

1.5" NPT |

19mm (3/4") |

45m (148 ft) |

25m (82 ft)

|

|

1000 Liters (264 Gallons) |

263 kg (579 lb) |

270 Kg (594 lb) |

2050mm (81") |

50m (164 ft) |

35m (115 ft) |

|||||||

Why use a solar water heater tank?

Active solar water heaters utilize an antifreeze as the working fluid in the system. This fluid carries the heat collector from the sun to a tank stored in a different location. In order to exchange heat to the water within the tank, a heat exchanger is required. Our solar water tanks come with a built-in copper heat exchanger, so the working fluid can simply pass through the coil, thus heating the water inside.

If a tank without a built-in heat exchanger is to be used, an external heat exchanger must be utilized to exchange the heat to the water. This will also require a 2nd circulation pump, as the water inside of the tank will need to circulate through the heat exchanger and back into the tank in order to collect heat from the working fluid, which is also circulating through the heat exchanger. Use of a solar water heater tank with a built-in heat exchanger minimizes needed parts to successfully operate a system and reduces heat loss to the outside environment.

Stainless Steel Tanks Are Better than Vitreous Enamel Tanks

Our tanks are made of food grade stainless steel layered with a galvanized steel shell on the outside for increased strength against high pressures. Stainless steel is superior in solar water heating applications because it can handle the very high temperatures produced by solar water heaters, has excellent corrosion resistance and can handle the constant high pressure resulting from constant heating throughout the day.

Vitreous enamel tanks are made of carbon steel and utilize a glass lining to protect the steel from corrosion. Unfortunately, these cheaper style tanks cannot handle the constant pressure in solar water heater systems. When the water temperature rises to 70°C or greater, which is typical for a solar water heater system, there is high risk of cracking of the glass lining due to excessive expansion and sticking to the carbon steel. Once cracks have formed, the carbon steel may rapidly corrode due to exposure to the water, which often results in premature failure.

Copper Heat Exchange Coils

Every tank comes with a copper coil in the bottom of the tank for heating by the solar loop. The coil extends from where the ports enter and down to the bottom of the tank so that the entire tank of water can be heated fully by the solar loop.

Dual coil tanks come with a 2nd coil installed on the top. This coil can be used for many different things, separate from the solar system. Some examples include:

1. If a user has a a boiler, the working fluid can pass through this coil as backup heating of the tank when temperatures run below the minimum temperature.

2. The top coil can be used for recovery of heat for another system such as radiant floor heating or a radiator somewhere else in the system where using the solar loop fluid directly in the radiator is not preferred.

Electric Back-up heating

All tanks come equipped with a 220/240v electric backup heating element. The element is not UL listed. The tank comes with a standard screw-in 1" port which accepts most standard water heating elements. Should the user wish to install a different heating element, it can easily be swapped out. The tank has a built-in thermostat for operation of the element independent of the solar system. The maximum amperage this thermostat can handle is 25 amps. The maximum the on/off switch on the element housing is 16 amps. If a higher amperage is to be used, simply do not wire to the switch and only use the thermostat and your household breaker for turning the element's power off or on.

Our solar water heater controller may also be used for operating the electric backup heating element in conjunction with a relay. The controller can activate the relay which provides power to the element. The advantage to using our controller is that it can be set to only run during certain times of the day so that there will not be any backup heating when water will not be in use such as during 3am. For small households which use water at only specific times, this may offer an advantage.

The electric backup heating element is considered optional. If it is not hooked up, the tank will still operate normally without backup heating. Users may wish to leave the element disconnected if

Note on Dual Coil Tanks: The upper coil is in the middle of the tank. On the smaller diameter tanks, users may find it a little difficult to install a long water heating element into the tank as it can collide with the coil. Since these tanks use electric water heating elements as backup heating only, a large element is usually not necessary so this is often not a problem.

Features

Safety/Control

Equipped with several automatic control and protection devices such as thermostatic control, over-temperature protector, pressure protection device and one way valve.

Magnesium Rod

Our tanks come with a magnesium anode rod. Magnesium rods work as a sacrificial anode. It will corrode before the other metals in the tank due to it being less noble than the stainless steel and galvanic outer shell. This is especially useful in helping to prevent pitting of the stainless steel. Magnesium rods are the best in soft water conditions. If your area has very hard water, it may be beneficial to consider an aluminum rod instead. Replace the magnesium rod every 3-5 to help preserve the tank for as long as possible.

Casing

The casing of the tank is made of a zinc-galvanized board with static powder coating and a baked finish which resists rust, ultraviolet rays and decoloration from long-term use.

Large Applications

Several tanks can be installed in parallel when accommodating larger systems with higher water demand. Streams of water can be distributed equally.

Operation Recommendations

Pressure

The water supply pressure should not be higher than 100 psi. In the case of higher water supply pressure, install a water pressure regulator valve. It is best to run the tank at 60 psi or less. Since the sun heats the tank often, a lot of water will be lost through the T/P valve from rising pressure. Use expansion tanks as necessary to prevent water/heat loss.

Additional Recommended Accessories

Thermostatic Mixing Valve. Since the sun can be variant based on weather and the seasons, it is best to install an in-line thermostatic mixing valve to control the outlet temperature of the hot water from the tank. When the tank is extra hot, it will mix cold water with the hot water to make the perfect desired temperature. This offers safety protection from especially children in the household, but more importantly, helps conserve heat that is wasted in the pipes from un-used water. It's better to mix automatically at the tank than manually at the faucet!

Manufacturer's Warranty Period:

All of our solar products come with a manufacturer's warranty. A manufacturer warranty covers materials defective due to the manufacturing process. If a manufacturing defect is discovered during the manufacturer's warranty period, the item may be returned to Duda Energy for repair or a replacement. Only materials found defective due to manufacturing will be replaced under the warranty. The warranty does not cover natural phenomenons such as corrosion.

The manufacturer's warranty period does not designate the expected lifetime for a material, unit or device. It only applies a limited time period in which defects due to manufacturing may be eligible for a claim.

Solar Tank Warranty Period: 2 Years

| WARNING: This product can expose you to chemicals including lead which is known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov. |

| Average Rating: |

Write a review |

Customer Reviews:

|

Heat Exchangers | Pumps | Filters | All Chemicals | Fluoroelastomer Hose (Like Viton Hose)

Other Chemicals | Solenoid Valves | Stainless Steel Fittings | Stainless Steel Ball Valves | Check Valves

Cone Tanks | Solar Water Heaters | Propane Conversion Kits | LED Lighting

Magnetic Stirrers